You may have wondered at some point: What is a polymer? Although this is a widely used material, its meaning is often not well understood.

Polymers are macromolecules composed of smaller units called monomers. These monomers are linked through chemical reactions to form long chains, either linear or branched.

At Excellent Cork, as manufacturers of synthetic corks, we understand the importance of this substance. That’s why we’ve prepared this article to discuss the types of polymers and their most common applications. Let’s dive in!

Types of Polymers

Polymers are essential in our lives due to their versatility, adaptability, and wide range of properties. They can be natural or synthetic, making them suitable for different industries.

There are various types of polymers, categorized as follows:

- Natural Polymers

- Synthetic Polymers

- Semi-Synthetic Polymers

Natural Polymers

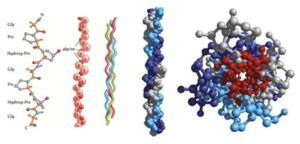

**What are natural polymers?** These are macromolecules found in nature and play a fundamental role in life on Earth. They are crucial to the structure and function of living organisms. The main types include:

- Proteins

- Nucleic Acids (DNA and RNA)

- Polysaccharides

Natural polymers are used to manufacture products like bio bottle corks.

Synthetic Polymers

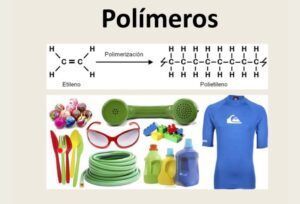

Unlike natural ones, synthetic polymers are man-made macromolecules created through chemical processes that transform monomers into long chains with specific properties.

These polymers have been key to industries because of their versatility and ability to be produced in large quantities. Some types include:

- Polyethylene

- Polypropylene

- Nylon (polyamide)

Polyethylene

Semi-Synthetic Polymers

Semi-synthetic polymers are materials derived from nature but modified to enhance their capabilities and increase adaptability. These combine natural advantages with manual customization. Examples include:

- Celluloid

- Cellulose Acetate

- Rayon

Classification of Polymers

Did you know there isn’t just one type of polymer? That’s right! They can be classified into three main categories: by structure, origin, and thermal behavior.

Each category has unique qualities, allowing them to be categorized for various uses. The choice of a polymer depends on specific needs, such as final product requirements and the conditions it will face during manufacturing and use.

By Structure

Polymers can be classified based on their structure, as their composition affects their properties. The three main types are:

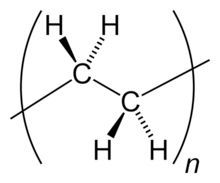

- Linear Polymers: Consist of monomers linked in a continuous linear sequence. Examples include polyethylene (PE) and polypropylene (PP). These polymers lack branching or cross-linking, resulting in high density and compact structure. They also exhibit good crystallinity, leading to **transparent polymers**.

- Branched Polymers: Feature a central chain with branches of varying size and frequency. These have lower density, reduced crystallinity, and diverse properties. Examples include low-density polyethylene (LDPE) and branched polypropylene.

- Cross-Linked Polymers: Form a network of interconnected chains through cross-links. These polymers are thermally resistant, highly rigid, and non-reprocessable. Examples include **liquid polymers** like epoxy and thermoset polyester resins.

By Origin

Polymers are also classified by their origin into two subcategories: natural and artificial. They are categorized based on their source and production process.

- Natural Polymers: Found in nature and living organisms, these polymers are vital for biological functions. Thanks to their unique properties, they are used in various applications. Examples include biopolymers, nucleic acids, natural gums like latex, proteins, etc.

- Artificial Polymers: Also known as synthetic polymers, these are created through chemical processes in laboratories or industries. They are not found in nature and are designed to meet specific needs. Examples include nylon, polycarbonate (PC), silicone, and acrylic (PMMA).

By Thermal Behavior

Polymers can also be categorized based on their thermal behavior when exposed to temperature changes. There are three subcategories, each with unique properties and performance under different conditions.

- Thermoplastics: Soften when heated and harden when cooled. They can be molded and remolded throughout their lifecycle. Their key properties include reprocessability and great flexibility. Examples are polyethylene (PE), polypropylene (PP), acrylic (PMMA), and polycarbonate (PC).

- Thermosets: Unlike thermoplastics, thermoset polymers are permanently fixed after curing. They cannot be melted or remolded, offering high heat resistance and durability. Examples include thermoset polyester, epoxy resin, and melamine.

- Elastomers: These polymers exhibit high elasticity and can stretch significantly before returning to their original shape without damage. Examples include silicone, natural rubber, and nitrile.

Applications of Polymers

Polymer Applications

Polymers have a wide range of applications due to their versatility and durability, making them essential tools in various industries and fields.

Here are the main uses:

- Textiles and Clothing: Used to make garments and upholstery, polymers like nylon, rayon, and polyester are durable and easy to maintain.

- Packaging: Products like PET bottles, plastic bags, and food wraps made of polyethylene (PE) or polypropylene (PP) are common applications. Also, wine bottle corks.

- Automotive: Polymers like polyamide are used in interior components, while nylon and polyester are used in gears and engine parts.

- Medicine: Polypropylene (PP) and polyethylene (PE) are used in medicine for drug packaging and disposable products. Silicone and other biocompatible polymers are employed in prosthetics and medical devices.

- Construction: PVC is widely used for pipes and flooring materials.

- Sports: Nylon and polyester are used in tennis rackets and sportswear for their flexibility and durability.

- Electronics: Polymers like polycarbonate (PC) and acrylic (PMMA) are used in casings and screens due to their impact resistance and transparency.

At Excellent Cork, we continuously strive to improve the quality of our synthetic corks by incorporating durable and resistant materials. Feel free to contact us to learn more about our products!

Frequently Asked Questions About Polymers

We understand that the world of polymers and their application in synthetic cork manufacturing can raise many questions. Below, we provide answers to some of the most common inquiries about this topic:

What is the difference between a monomer and a polymer?

The fundamental difference between a monomer and a polymer lies in their size and structure. Monomers are small molecules that can chemically bond with each other. When several monomers link together through chemical reactions, they form polymers, which are macromolecules with more complex structures. Polymers are essential in the manufacturing of synthetic materials, such as corks, thanks to their mechanical properties and versatility.

What is a thermoplastic polymer, and why is it important in synthetic cork manufacturing?

A thermoplastic polymer is a type of material that becomes malleable when heated and can be molded into different shapes. When cooled, it hardens and retains its acquired form. This process is reversible, meaning it can be repeated without the material losing its properties. Thermoplastic polymers are crucial in synthetic cork manufacturing because they allow mass production of high-precision parts and are recyclable, contributing to environmental sustainability.

What are the most common uses of polymers in the industry?

Polymers are incredibly versatile and are used across a variety of industries. Some of the most common uses include:

- Textile Industry: For the production of synthetic fibers like nylon and polyester.

- Packaging: In plastic bags, bottles, and food containers.

- Construction: In pipes, windows, and insulating materials.

- Medicine: In medical devices, prosthetics, and pharmaceutical packaging.

- Automotive Industry: In interior components, tires, and mechanical parts.

- Synthetic Cork Manufacturing: Used in industries such as winemaking and food to ensure efficient and durable sealing.

What advantages do synthetic corks offer compared to natural corks?

Synthetic corks, made from polymers, provide several key advantages over natural corks, including:

- Uniformity: Being industrially produced, they have consistent quality without the natural imperfections of cork.

- Durability: They are more resistant to humidity and temperature fluctuations.

- Eliminates TCA Risk: Natural corks can develop trichloroanisole (TCA), which negatively affects wine flavor. Synthetic corks eliminate this risk.

- Customizable Options: They can be designed in various colors, shapes, and with specific features, such as easier extraction.

How is sustainability ensured in synthetic cork production?

Sustainability in synthetic cork production is addressed through several strategies:

- Use of Recyclable Polymers: Many synthetic corks are made from materials that can be recycled at the end of their lifecycle.

- Energy Efficiency: Modern polymer manufacturing processes are optimized to reduce energy consumption.

- Waste Reduction: Manufacturing processes ensure precise material control, minimizing waste.

- Research into Biopolymers: Some manufacturers are developing polymers derived from renewable sources, such as corn or sugarcane, to reduce dependence on fossil resources.

How are synthetic corks manufactured?

Synthetic corks are primarily produced through the injection molding of polymers. In this process, thermoplastic material is melted and injected into a mold shaped like the desired cork. Once the polymer cools and solidifies, it is extracted from the mold, resulting in a perfectly formed cork. This process is highly efficient, allowing the production of large volumes in a short time while maintaining high precision in measurements and product characteristics.

Are synthetic corks safe for contact with food?

Yes, synthetic corks are designed to meet the strictest food safety regulations. The polymers used are food-grade, ensuring they do not release harmful chemicals or alter the organoleptic properties of the contents. Additionally, their design prevents any risk of external contamination, providing a hermetic and safe seal.

If you need further assistance or information about this topic, feel free to ask!